Parts that are remanufactured into a renewed life are the equivalent to new,

in terms of quality and reliability performance

What is Remanufacturing?

Remanufacturing has been defined in the British Standard, BS 8887-2, as a process that involves “returning a used product to at least its original performance with a warranty that is equivalent to or better than that of the newly manufactured product”.

The inclusion of the remanufacturing definition in a UK nationally recognised standard is the first step in enabling remanufacturing to be recognised as a viable option for reducing both the environmental impact and the overall cost of products.

Our remanufactured parts are returned products, which undergo a professional and comprehensive revision process.

Remanufactured parts aren't just repaired, refurbished or reconditioned....remanufacturing is far more extensive than simply reworking parts.

During the professional remanufacturing process, all of the wear-sensitive parts are replaced, whether they are defective or not.

The parts will be thoroughly inspected and cleaned in accordance with pre-defined procedures.

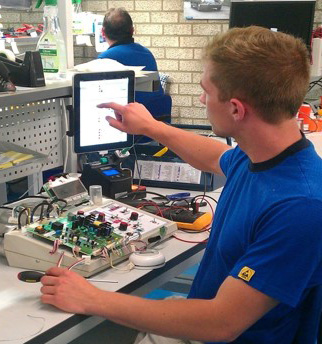

Each part will be subject to a 100% functionality test which guarantees a constant quality output.

"Our remanufactured parts into a renewed life

are the equivalent to or even better than new,

in terms of quality and reliability performance"

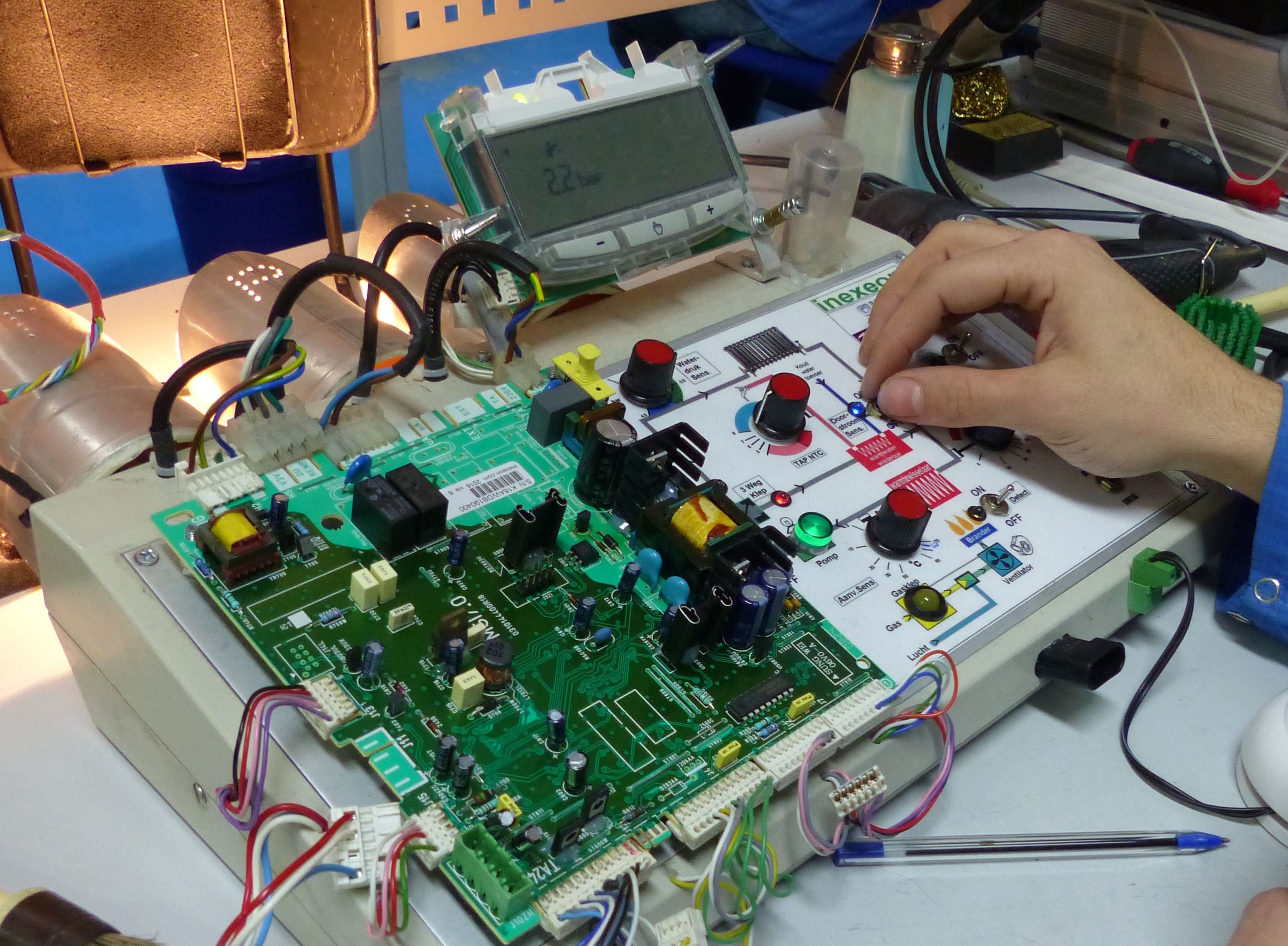

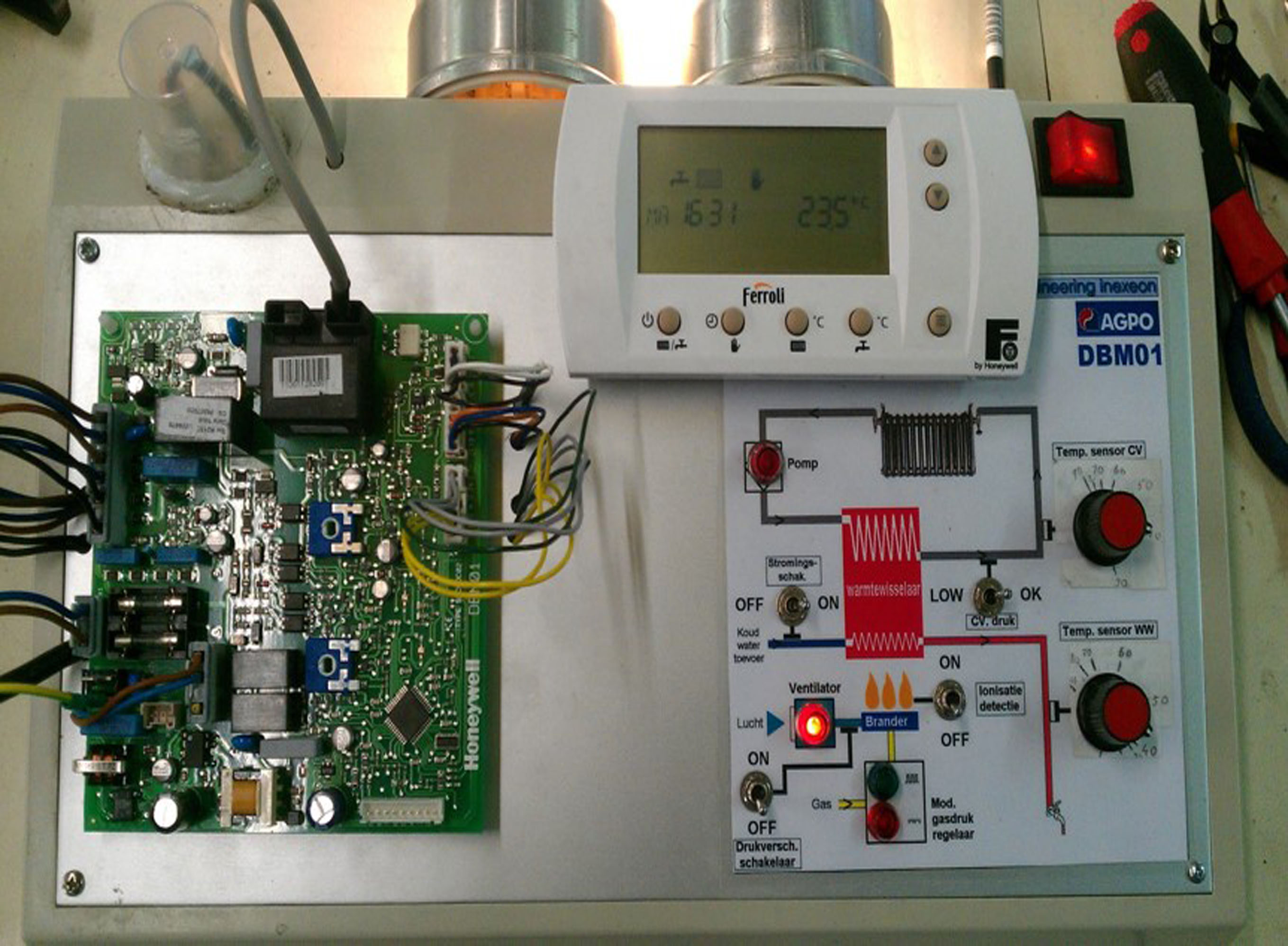

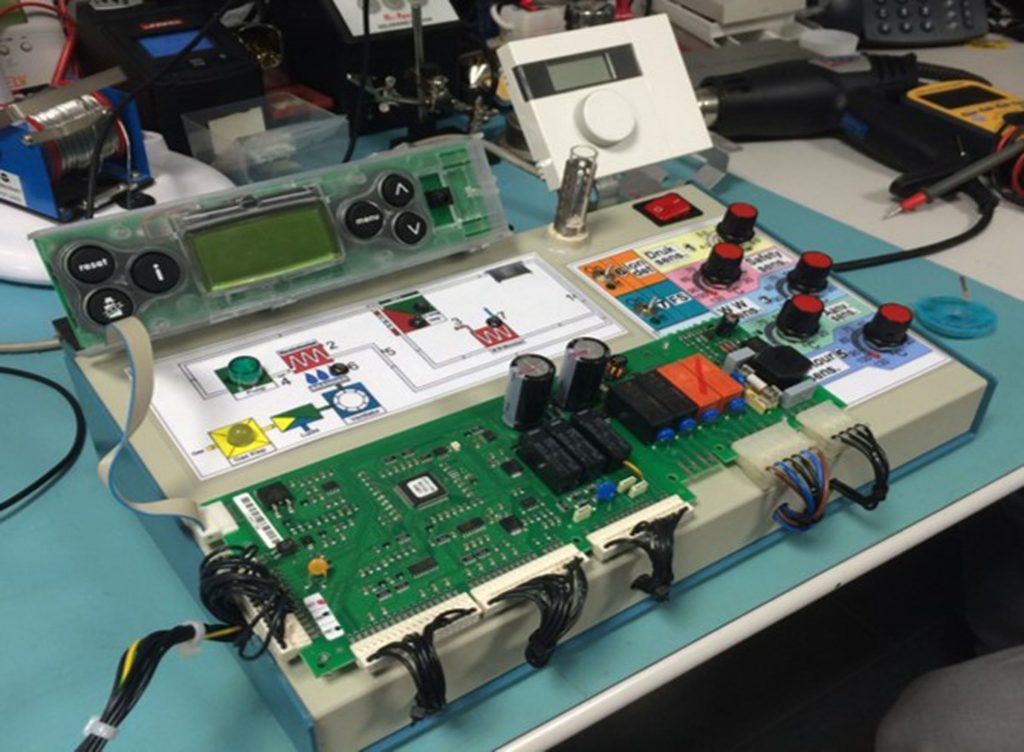

PCB test devices

Each PCB requires a specific, for testing purpose developed, test device to perform a 100% functional test. These test devices are designed and made in house by the engineering department.